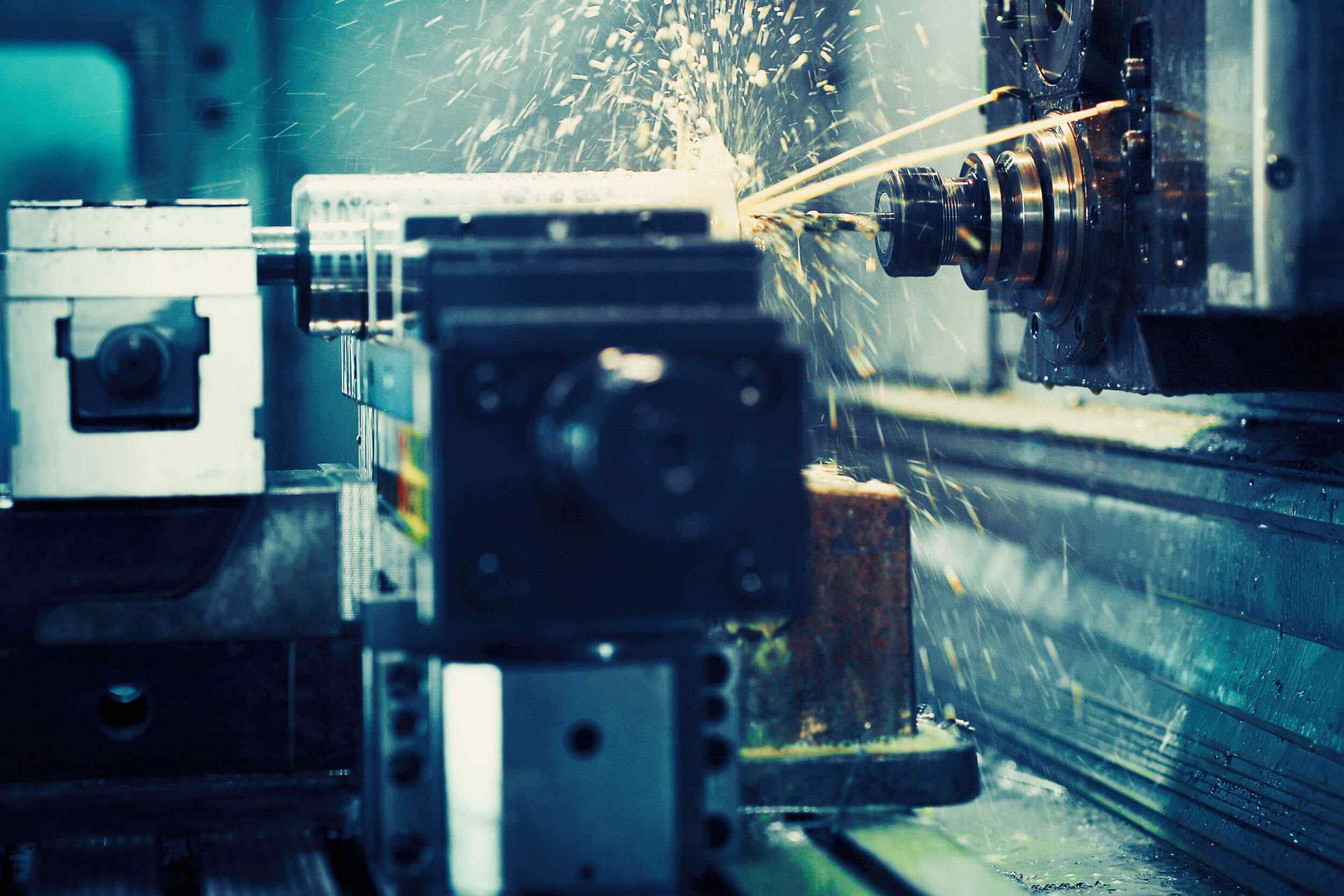

Diverse Manufacturing Methods

Welded steel pipes utilize various manufacturing methods, including resistance welding, high-frequency welding, submerged arc welding, etc., to meet different engineering requirements.

Economical and Practical

Compared to seamless steel pipes, welded steel pipes have lower manufacturing costs, making them suitable for mass production and economical applications.

Wide Range of Specifications and Sizes

Offered in a diverse range of specifications and sizes to accommodate various application scenarios and meet the needs of different industries.

Reliable Welding Quality

Advanced welding technologies and process controls ensure reliable welding quality, resulting in strong and durable weld seams.

Applicable to Various Environments

Depending on requirements, welded steel pipes can undergo anti-corrosion treatments, making them suitable for different corrosive environments.